SC200-480

Robot compatibility:

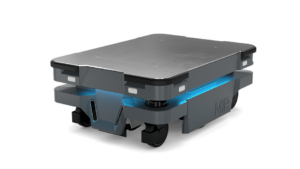

MiR100, MiR250

Nord Modules compatibility:

Quick Mover 70, Quick Mover 220

Dimensions (LWH):

894 mm x 615 mm x 591 mm (MiR250) or 643 mm (MiR100)

Handling capacity:

300 kg

Max payload on shelf:

40 kg UDL (Uniform Distributed Load)

Cart Kit:

4 x shelfs, 4 x long shelf pillars, and 4 short shelf pillars

Description

The NORD Shelf Cart merges with our Quick Mover installed on a MiR robot, to receive or deliver objects placed on the Shelf Cart anywhere in the production site.

The NORD Shelf Cart can be mounted with any individual application or solution the customer might wish for. Due to the design of the Shelf Cart, the AMR can recognize when it is under the cart to transport it around.

What is a Shelf Cart?

It’s a rack on wheels interacting and moved by AMRs (Autonome Mobile Robots) like MIR.

- Deliver/pick up goods from gates

- Ensure accurate and easy delivery

- Handle all different kinds of goods

- Transport goods from A to B

- Can be expanded by a Cart Kit

How users can benefit

- Automated move of goods with a MIR Robot (an Autonomous Mobile Robot - AMR).

- Use standard ISO size trolley components.

- Assembled at customer site makes delivery costs low.

- Space of trolleys can be reduced when not in use / by return transport.

- Shelves supports ISO modular (E.g. 200 x 200 mm/ 400 x 600 mm /600 x 800mm).

- Save manual handling, stock- and transport costs.

- Reduce noise from wheels with a special surface.

- Designed for flexible heights and setting intervals (numbers) of shelves.

- Designed for automation, AI, IOT, AMR and driverless trucks.

- Better exposure / access to goods with sloped shelves.

- Improves logistic processes by use of RFID-tags, GRAI- and BAR-codes.

- It saves labor costs and enhances the efficiency and the working environment.

- Improves functionalities and logistics at all B2B companies.

- The unique system for mounting the shelves is patented.