What is an AMR?

An autonomous mobile robot without a top module lacks functionality – just like a robot arm without a gripping tool. And the prospect of a growing market for mobile robots thus spills over into the top module area. At Nord Modules A/S, we aim to help both AMR manufactures and end customers by providing high quality, multi functional, and long lasting top modules for the top AMR brands and their robots.

AMR stands for Autonomous Mobile Robot.

They are self-driving and self-navigating robots that are used to transport material around from point a to point b. AMRs are collaborative, which means they are made to work together with humans. They are equipped with sensors which they use to navigate around obstacles and which also enable them to stop if a person suddenly walks out in front of the robot.

The market for autonomous mobile robots is growing rapidly, as more and more companies see the value in optimizing their production and turnover with the help of automation. If, for example, a product or component is to be transported from storage to a production unit, an AMR solution will be flexible, space-saving, efficient and quick to implement.

Alternatives could either be conveyor belts, an employee in a truck or with a pallet lifter, or a more elaborate integration of semi-automated carts. Whether you choose one or the other obviously depends on the specific case, but an AMR solution will, in the vast majority of cases, be the most optimal.

Read our Introduction to Mobile Robots blog post for more information about AMRs

Why are top modules needed?

An AMR without a top module lacks functionality, just as a robotic arm without a gripper or other end effector, lacks functionality. Top modules are what make the mobile robots functional and able to solve specific tasks without the need for manual input. A top module can, for example, enable the robot to load and unload itself, which can be a necessary feature in an automated process.

When implementing automation with AMRs, the specific task to be solved should first of all be looked at. Once the task is defined, you should find the top module that best solves the task and then see which AMR model fits.

Nord Modules

At Nord Modules A/S we specialize in producing top modules for AMRs. Nord Modules offers a number of standard module solutions which are AMR agnostic, which means that the same solutions can be used for a number of different AMR brands. Nord Modules offers several standard solutions within the transport of goods with AMR.

Some of these AMR solutions include:

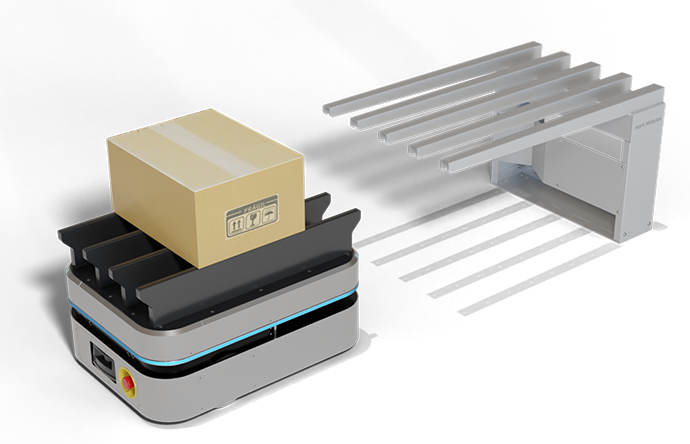

- Quick Mover – The Swiss Army Knife of top modules for transporting goods. The Quick Mover is equipped with fins that can be raised or lowered, which allows the module to be loaded and unloaded. The Quick Mover works together with Nord Modules’ wide range of Gates and/or together with the Shelf Carts.

The Quick Mover is available in different sizes depending on how heavy the goods to be transported are. - Pallet Mover & Pallet Conveyor – A complete transport system for pallets that can handle heavy loads and pallets of various sizes. The Pallet Mover is the top module itself, and the Pallet Conveyor is a conveyor belt module that loads the pallet onto the AMR. The two modules talk to each other via a wireless connection, so that the Pallet Mover can notify when the AMR is docked and ready to receive a pallet.

Nord Module’s products are characterized by high quality, reliability and, not least, safety. The products are all equipped with a high level of feedback, which ensures stable operation.

Growing market demand

According to a report by Verified Marked Research, the market for mobile robots, globally, was estimated to be approx. Worth USD 27.1 billion in 2020, and it is expected to reach USD 160 billion as early as 2028, which gives an annualized multi-year growth rate of over 24 percent.

The market for top modules for autonomous mobile robots is only a small part of the total market for mobile robots, but at Nord Modules in Odense, you can clearly see that the demand for top modules is increasing.

“We are experiencing increasing demand from many different countries and from many different types of companies. These are both smaller production and storage companies, but also from some of the very large well-known brands in and outside Europe. There is a great focus on automating and optimizing rather than outsourcing production, and this means that the factories need to implement robotic solutions.” Says Kristian Kvistgaard, CTO at Nord Modules.